Vital water

SCA has met its previous water targets and has therefore introduced new targets that are adapted to local conditions, as water is a local issue. The new targets apply to all mills and focus on treating water as effectively as possible, as well as reducing water usage.

Water is a critical resource and, along with climate change, is one of the most critical sustainability issues facing the world today. We have every reason to treat, reduce and rationalize water usage at every SCA plant.

SCA mainly uses water to transport fibers, and for cooling in the production process. Most of our plants, which account for 97% of our water usage, are located in areas with a plentiful supply of water.

This is the first year we are reporting in accordance with our new water targets. The targets have been established based on what is most relevant. Water usage is not as big an issue in Sweden as it is in water-stressed regions, such as Colombia or Spain. However, it is important in Sweden to reduce phosphorous emissions as they can have a negative impact on the Baltic Sea. The increase in phosphorous emissions during the year resulted from disruptions and problems with measurement equipment at the Obbola facility in Sweden.

TARGET

Our plants will reduce suspended solids by 10%.

Our tissue operations will reduce the water usage by 10% and organic content (BOD) by 10%.

Our forest products operations will reduce phosphorous emissions by 10%. All targets will be achieved by 2020 (reference year 2014).

OUTCOME 2016

Our plants reduced suspended solids by 12.5%.

Our tissue operations reduced the water usage by 1.5% and organic content (BOD) by 3.3%.

Our forest products operations increased phosphorous emissions by 35.6%.

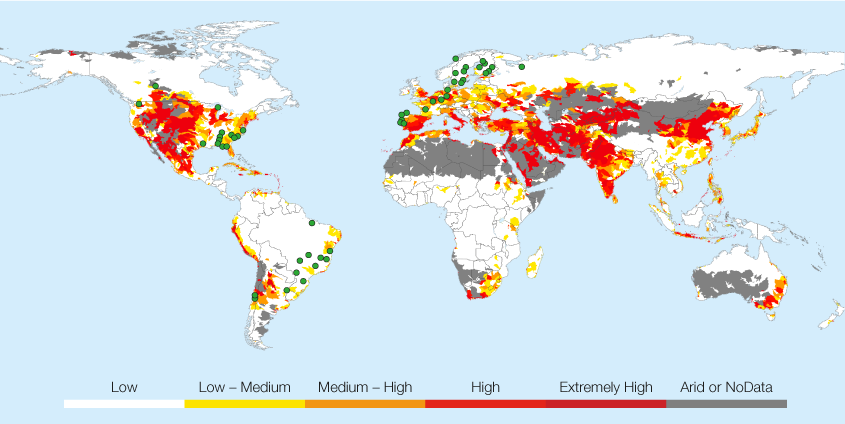

Water risk assessment

Red color indicates a high water stress, white a low. SCA’s plants are generally located in areas with favorable access to water.

Source: WRI, GADM

For the first time, SCA has conducted a water risk assessment at all of its pulp suppliers. In total, 54 suppliers were evaluated, and most are located in low-risk areas or regions.

Pulp production requires large volumes of water and we therefore need to ensure that our suppliers’ production is not associated with high water risks. We used the external tool WRI Aqueduct that considers multiple risk factors but mainly risks related to water quantity, water quality and regulatory risks. Only a few suppliers are located in areas with medium to high risk.

“We have no high-risk pulp suppliers with regards to water,” says Armin Benner, environmental specialist at SCA. “Now we will evaluate the results and based on this thorough analysis, we will decide if it is necessary to replace or reduce volumes from any supplier.”

The water risk assessment will be updated on a regular basis and we will also look into other key supply streams. SCA has evaluated water risks at its own production sites since 2011.

ÖSTRAND DOUBLES EFFLUENT TREATMENT

SCA is expanding effluent treatment at its Östrand pulp mill in Sweden, as part of a major investment at the facility. The investment will double production capacity and this will also require a higher water flow. Östrand’s hydraulic capacity will increase from 2,000 to 4,000 cubic meters of water per hour. This increase will primarily be through an expansion of existing technology, as this has been functioning effectively.