Climate and energy

SCA’s efforts to reduce its climate impact and energy use are manifested through numerous projects, investments and modifications of processes, all of which contribute individually to the target of reducing CO2 emissions.

Results 2016

At year-end 2016, CO2 emissions in relation to the production level had declined 18.4%, compared with the reference year of 2005.

Science-based carbon target

SCA has committed to a science-based target for the reduction of greenhouse gas emissions in its hygiene operations. This will be established in 2017 and SCA expects that extensive investments and action will be required to achieve the target.

Reduction targets are considered science-based if they are in line with what is needed in order to keep the global temperature rise below 2 degrees Celsius, as agreed by world leaders at the UN climate change conference (COP 21) in Paris in 2015. The Science Based Targets initiative is a partnership between CDP (formerly known as the Carbon Disclosure Project), the UN Global Compact, the WRI (World Resources Institute) and the WWF (World Wide Fund for Nature). Science Based Targets help companies determine which emission reductions they need to achieve in order to prevent the worst impact of climate change. Read more at sciencebasedtargets.org.

Investments

Investments in new technologies and upgrades to existing solutions play a significant role in SCA’s ability to achieve its CO2 target.

In cooperation with local partners, SCA has invested in a new biofuel power plant that provides SCA’s tissue plant in Nokia, Finland, with a low-cost, renewable and reliable energy supply. The investment has reduced annual carbon emissions by 29%, equivalent to 7,000 tons. The biofuel plant meets most of the paper mill’s steam requirements.

Together with external partners in the Netherlands, SCA is pioneering the use of pyrolysis technology to extract energy from sludge in its tissue plants. The technology has huge potential to reduce waste and carbon emissions. SCA will also reduce cost by converting waste into a carbon-neutral energy and minerals that can be sold as raw material. In December, a mobile pilot unit, which will be used for testing in the European and US mills, was finalized.

The company’s investments in a biofuel plant in Mannheim, Germany and in pulp production in Östrand, Sweden are described in chapter Climate and Energy.

ESAVE

Electricity consumption 2016

Electricity consumption 2016: 7,850 GWh

The majority of SCA’s electricity, 84%, comes from national grids, while 16% derives from electricity produced in the Group’s co-generation plants.

Since 2003, SCA’s ESAVE energy-efficiency program has contributed to energy savings and improved efficiency in all operative business units. In 2010, SCA adopted a target for ESAVE: to reduce energy consumption per ton of product produced by 14% by 2020. In 2016, 101 ESAVE projects were implemented, resulting in a 0.9% (0.5) year-on-year reduction in energy used per ton of product produced. The accumulated energy savings in the 2010–2016 period amounted to 9.0%, corresponding to a 1.8 TWh reduction in energy consumption.

Energy-efficiency improvement is an integral part of daily life at SCA and ESAVE is a process, not a project. It encompasses investments in energyefficient technical solutions, the involvement of employees in daily improvement activities and a general change in attitude toward the use of energy at SCA. Knowledge sharing is leveraged across the company through training and network events and ESAVE is part of several onboarding programs for young engineers. Best practices are shared online, in real time, to achieve energy-efficiency excellence by learning from others. SCA also cooperates with external stakeholders, such as machinery suppliers, to ensure continued leadership in energy efficiency and continuous improvements. All new equipment is energy efficient by design and ESAVE is part of the planning criteria.

A typical ESAVE project could involve reducing electricity consumption by improving or replacing pumps, compressors, fans or lighting, or by optimizing thermal drying processes. Experiences are documented and provide effective support for future improvement efforts.

MSAVE

SCA has also introduced a material savings program, MSAVE, using the same philosophy and methodology as in ESAVE. The program aims to achieve the best overall cost and minimize the environmental impact from raw materials and waste. Best practice is shared across the sites worldwide.

Examples of MSAVE initiatives include optimizing the tissue machine fiber mix and chemical dosage scheme, reducing the amount of packaging materials used in our products, re-using the tissue waste in our processes as well as converting waste into by-products to be used as raw materials in other industries and partnering with local industries.

Transport

Fuel consumption 2016

Fuel consumption 2016: 61,322 TJ

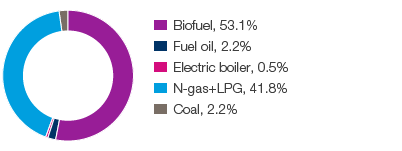

A total of 42% of SCA’s fuel consumption comes from natural gas and 53% from biofuel. Oil and coal account for 5% all together.

SCA monitors the environmental impact of its transport activities and is working on a broad front to reduce emissions. These efforts include increasing the fill ratio, applying various techniques to reduce fuel consumption, prioritizing transport means with less environmental impact, reducing distances travelled and strengthening purchasing procedures. The Group’s total carbon emissions from transport activities in 2016 amounted to 0.87 million tons (0.87, 0.87).

Shipping

Shipping accounted for 69% of SCA’s total transport activities. The Group owns three roll-on roll-off (RoRo) vessels which operate in Northern Europe between Sweden, Germany, the UK and the Netherlands. Other shipping services are mainly carried out with container vessels, but also with other cargo ships. European traffic was reorganized mid-2016, which means a larger share of transport is carried out with container vessels. The changes have cut costs, increased energy efficiency and reduced environmental impact. RoRo vessels account for about 9% of SCA’s transport usage by ship, with a total capacity to transport about 1,300,000 tons.

Road transport

25% of SCA’s freight is transported by road. SCA engages in a number of collaboration projects to cut transport emissions, including tests of vehicles using biomass-based fuels.

SCA was one of initially ten companies in France that signed a charter called FREIGHT21 with the Ministry of Sustainable Development in 2015 with the aim to reduce its CO2 emissions from (mainly road) transportation by 5% by 2018, corresponding to 1,500 tons. Half-way through, SCA in France has already fulfilled over 80% of its objective and reduced CO2 by about 1,300 tons. A cross-functional team, including logistics, CSR and communications, has focused on key aspects such as (1) drop-size and truck-fill rates, (2) multimodal transportation (use of rail transportation for deliveries from Sweden or the Netherlands to Spain), (3) distance and product flow optimization, and (4) product specifications (launch of compressed household towels).

Rail transport

Rail transport accounts for 6% of SCA’s total freight – this small share is partially due to restrictions in the rail network. Because rail transport is a carbon-efficient alternative, it is a prioritized transport means. SCA uses multimodal transport for distances exceeding 1,000 km. If there is no direct rail connection, SCA requests that its suppliers use rail to the greatest extent possible, supplemented by truck transport. If there is no, or a very small, price difference between alternatives, SCA will choose the solution with the least impact on the environment.

The EU Emissions Trading Scheme (ETS)

SCA had 31 mills and plants included under the ETS in 2016. SCA’s operations in the Nordic region will continue to produce a surplus, while its operations in the rest of Europe will have a certain deficit during the third phase of ETS (2013–2020). This balance provides an estimated total surplus of almost 2 million tons of carbon dioxide equivalents. The surplus is the result of the measures implemented by SCA over an extended period in the form of energy-saving activities, process optimization, choice of fuel and major investments. The average market price for emission rights in 2016 was about EUR 5.35 per ton and SCA sold 405,000 emission rights.